Paper Coating Operations

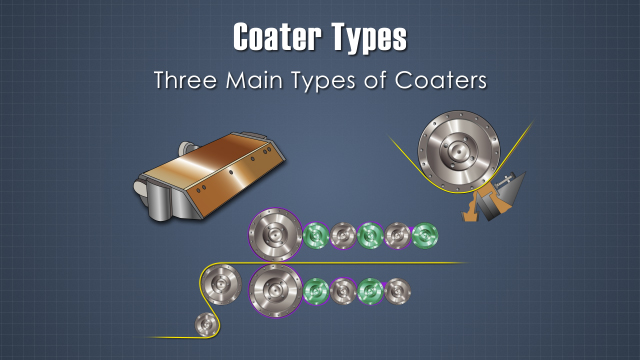

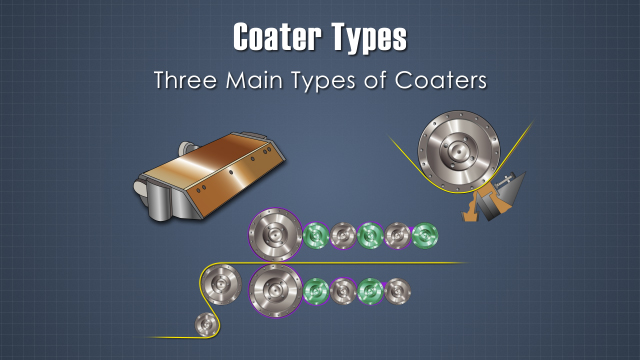

Paper coatings can be used to enhance the printability, visual properties or functionality of a sheet of paper board. Coating formulas vary widely because there are many different grades of coated paper and board with very different end uses. This module will identify the main purposes of paper and board coatings and describe the three most common coater designs.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Identify the main purposes of paper and board coatings • List the three main categories of coating ingredients • Identify and describe the three most common coater designs • List the three main objectives of coating equipment • List the advantages and disadvantages of air-knife, blade and roll coaters • Describe the three most common methods of drying paper coatings

Specs

Frequently Asked Questions

Why are there so many different coater designs?

Why is some coating done on-machine and some off-machine?

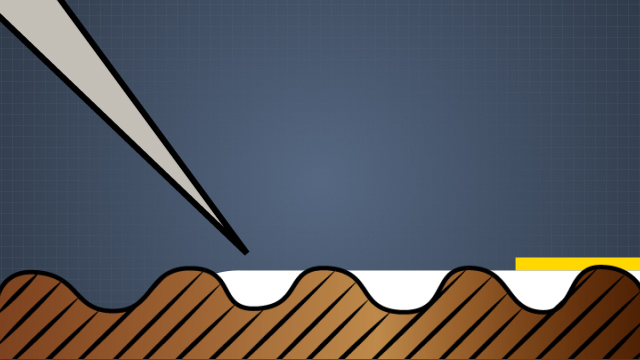

Which type of coater is best at filling in low spots in the sheet to create a smooth printing surface?

What is a “”contour coater””?

Why are other types of dryer equipment, besides steam-heated dryer cans, used to dry paper coatings?

Sample Video Transcript

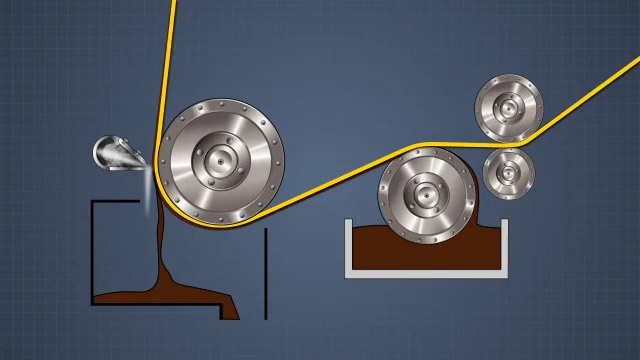

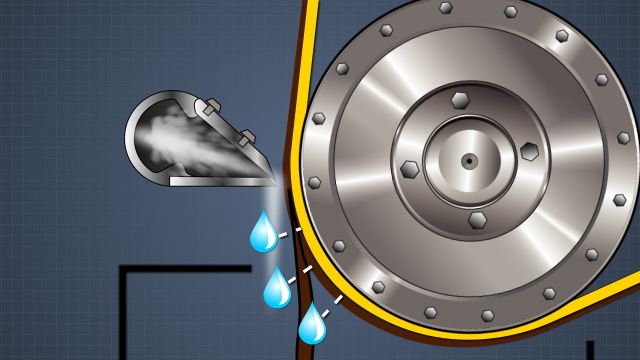

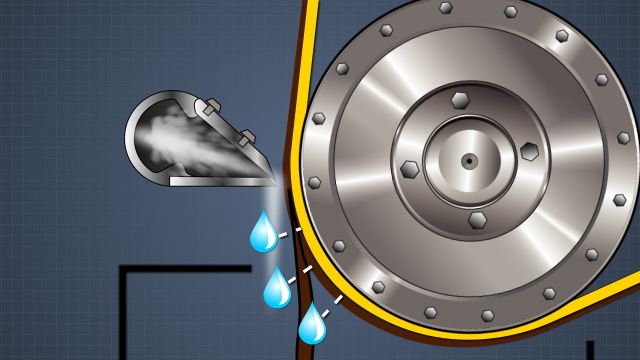

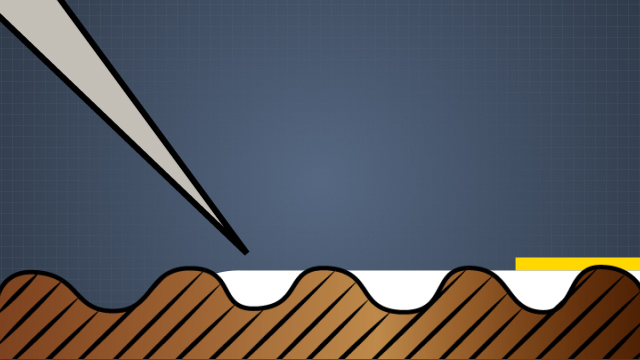

Air knife coaters operate on the principle of applying too much coating to the sheet and then removing the excess. A driven roll rotating in a coating solution filled pan applies a meter to the amount of coating solution to the sheet. Shortly after, the sheet travels around a backing roll and an air jet or air knife is directed onto the coated sheet surface to remove the excess. The excess coating is collected in an overflow pan so that it can be recirculated and reused. The air knife is set up to sheer off the excess coating near the sheet surface, where the water in the coating solution is beginning to absorb into the sheet. The velocity and energy of the air knife control the coat weight.