Paper Machine Doctors

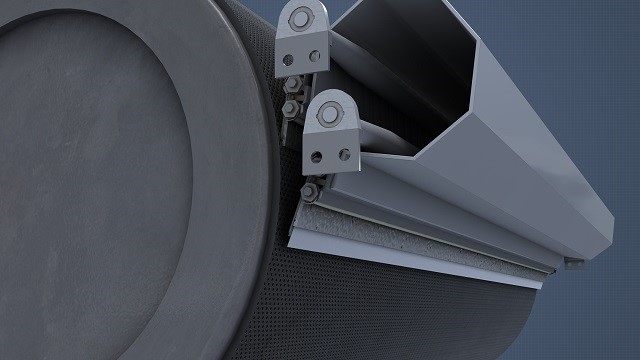

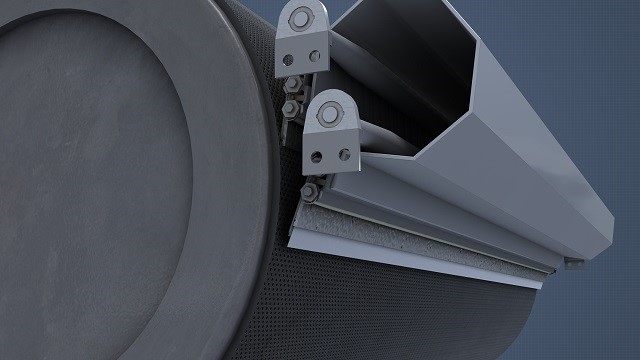

Doctors are used in all sections of paper and board machines to remove excess water and contaminants from roll surfaces. In some applications, they are also used to remove the sheet from roll surfaces on sheet breaks or during sheet threading. Doctors must be checked and inspected on a regular basis to ensure their continued, safe, efficient operation.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

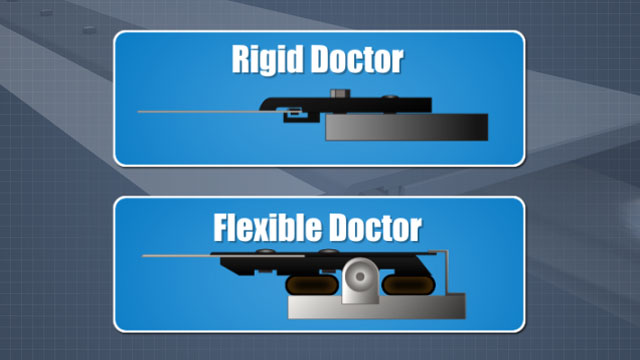

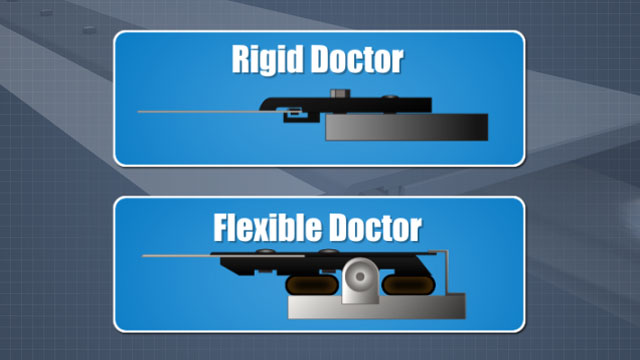

• Identify the two main functions of paper machine doctors • Identify and describe the safety hazards associated with roll doctors and doctor blades • Identify the key components of a doctor • Identify the purpose of the doctor components • Differentiate between mechanically-adjusted and self-conforming blade holders • Identify typical locations for doctors on paper and board machines • Explain the importance of regular doctor and doctor blade inspections • Identify and describe key inspection points for doctors and doctor blades

Specs

Frequently Asked Questions

Why are flexible, self-conforming doctor blade holders used on some rolls?

Why should you avoid increasing the load on a used doctor blade?

Why are double doctors used on some suction rolls?

Where are air doctors used on paper and board machines?

Why is it important to change doctor blades on a regular basis?

Sample Video Transcript

Double doctors are often used on the suction couch roll to improve moisture profile and runnability, minimize rewet of the sheet, and keep the roll shell clean. The first blade removes surface water and creates a vacuum pulse that pulls water out of the roll holes. This water is then removed by the second blade. The center press roll double doctor is often accompanied by a roll shower to keep the roll surface clean. This doctor is often used to remove the sheet to a broke chute. And so the doctor back must be designed to withstand the additional force required.