Wet End Chemistry Basics

Discusses the fundamentals of colloidal chemistry for paper machine stock and water systems. Describes the surface charge interactions that take place and the role of pH. Discusses how some commonly used chemicals affect wet end chemistry, machine operations, and sheet characteristics.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Identify the three major classes of furnish components • Define and describe a “colloid” • Describe two ways to measure charge • Describe the effect of furnish surface area on additive uptake • Describe coagulation and flocculation • Identify the sources of anionic trash and describe its effect on the system • Explain why water plays a large role in papermaking • Describe the pH Scale • Explain why pH control is important • Describe the two classes of papermaking additives • Identify common chemical additives and their purpose • State the importance of wet end chemistry control

Specs

Frequently Asked Questions

What is “wet end chemistry”?

What are “colloids”?

What are “anionic trash” and “cationic demand”?

Where does “anionic trash” come from?

Why is pH important?

Sample Video Transcript

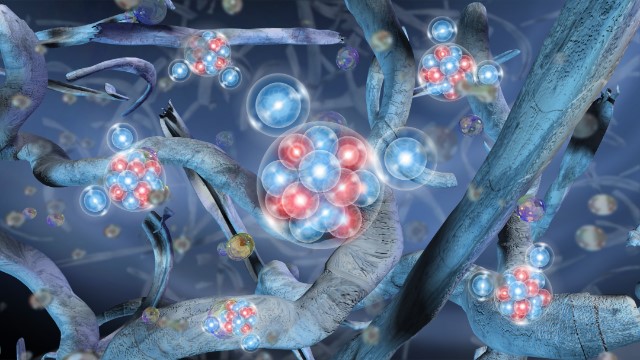

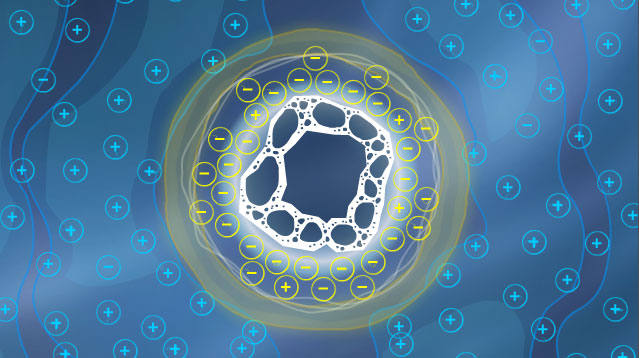

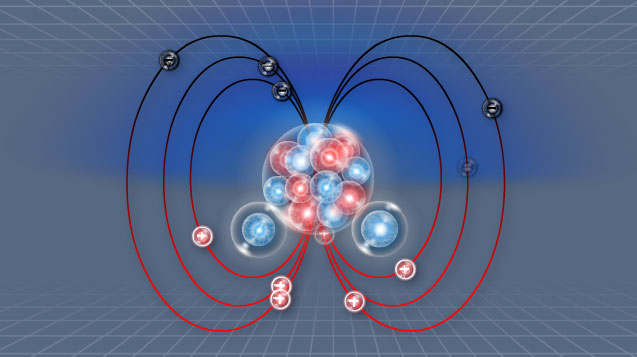

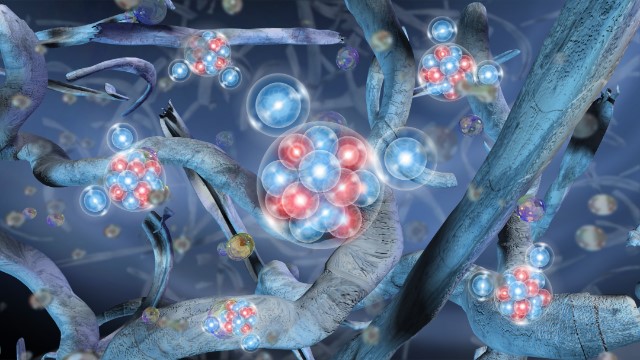

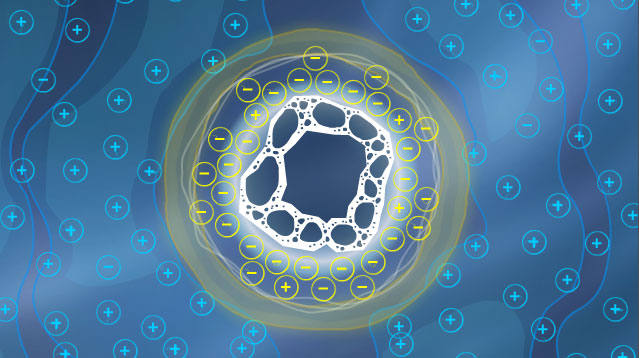

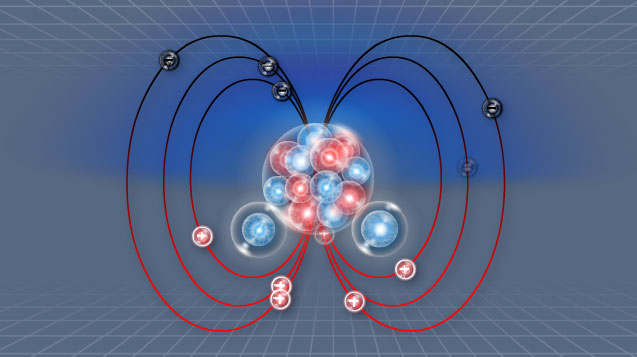

Wet end chemistry is dominated by colloidal chemistry because of the small size of the furnished components and because most chemical interactions occur at the component surfaces. Colloids are particles that do not easily settle out of a solution under the influence of gravity. They have very small particle sizes and very large surface areas. In fact, even the fibers can be considered to be colloids due to their small diameters and large surface areas. Colloids often carry an electrical charge on their surfaces that results from the presence of anionic, or negatively charged, and cationic, or positively charged groups. Wood fibers and fiber finds normally have negatively charged surfaces, as do many other furnished components. Because most molecular interactions in paper machine stock systems are surface-charge interactions, chemical additives must be carefully selected. The selected additives, plus their addition points and rates, must take into account the surface charge characteristics of the additives and all of the other furnished components.