Baghouse Basics

Baghouses are used in many different applications to remove particulate matter from air and gas streams. They typically have very high removal efficiencies, often over 99%. The fabric bags used in baghouses must be cleaned intermittently to remove the dust cake that builds up. This course discusses the cleaning mechanisms used in the three main baghouse designs – shaker, reverse air, and pulse jet. It also covers the different fabrics that can be used, filter canisters with pleated filter media, and sonic cleaning horns. When selecting or designing a baghouse, you must know several characteristics of the air or gas stream and the particles it contains. This course lists the critical design variables and also the calculations used to select an appropriate baghouse design and size it properly.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• List the three main purposes of baghouses

• Identify and describe the main components of a typical baghouse

• Identify and describe the operation of shaker baghouses

• Identify and describe the operation of reverse air baghouses, including continuous reverse air baghouses

• Identify and describe the operation of pulse jet baghouses

• Describe how cartridge filters, sonic horns, and inlet diffusers or deflectors can enhance baghouse operations

• List important variables for baghouse design

• Define the terms “air-to-cloth ratio,” “pressure drop,” “grain loading,” and “can velocity”

Specs

Frequently Asked Questions

Baghouses have been around for a while but they don’t seem very sophisticated. Why are they still sometimes used?

Why is it desirable to have the dust cake reform quickly on bag surfaces in a baghouse?

Can a baghouse be used if the particles being removed from an air or gas stream are combustible or explosive?

Must all baghouses be taken offline (i.e. the incoming air or gas flow be turned off) in order to clean the dust cake off the bags?

Why do some baghouses have an inlet diffuser and some don’t?

Sample Video Transcript

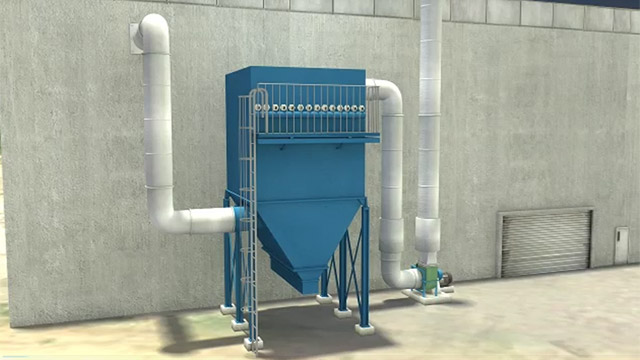

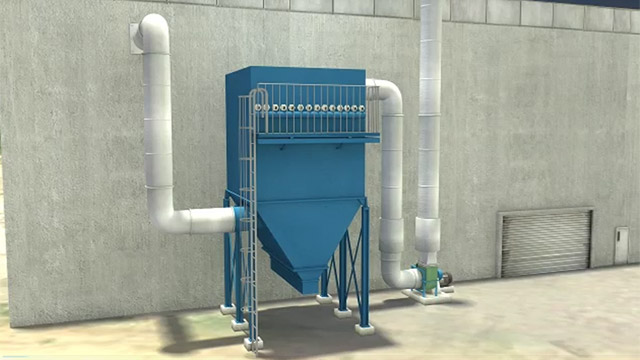

There are many different sizes and designs, but baghouses all operate in the same basic way. One, the dust latent or particle latent air or gas stream, enters the baghouse, travels along the surfaces of multiple fabric tubes, and then passes outward or inward through the fabric. Two, the larger particles fall down into a hopper, while the smaller particles accumulate on the fabric surfaces. Three, a cleaning mechanism occasionally removes the particles from the fabric tubes and they fall down into the hopper from which they are discharged. Four, the clean air or gas stream exits from the top of the baghouse.

Additional Resources

- EPA Air Pollution Control Cost Manual, 6th Edition, January 2002, Section 6 – Particulate Matter Controls, Chapter 1 Baghouses and Filters