Blow Line Refining Operation

Blow line refining is an important part of the industrial process that converts wood chips into paper and other useful cellulose based products. Blow line refiners typically operate downstream of a continuous digester and act to break apart cooked wood chips as they are discharged from the digester. This module will describe the purpose, components, and operation of blow line refiners.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe the purpose of blow line refining

• Describe blow line refining process theory

• Identify and describe the components of a blow line refiner

• Describe blow line refiner operation

• Explain the effects of refining on pulp properties

• Describe the safety hazards associated with blow line refining

Specs

Frequently Asked Questions

What is meant by “”refining”” of pulp?

What is one advantage provided by a blowline refiner?

What is the physical form of a refiner?

What in the primary operating parameter which controls of the amount of energy applied to pulp going through a refiner?

What is the effect of applying excessive energy to the pulp?

Sample Video Transcript

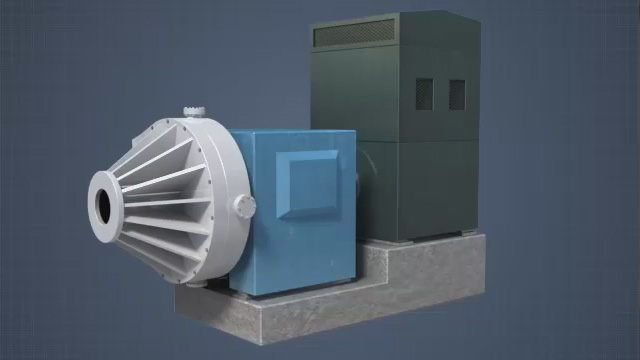

Refining action is caused by passing blown digester material, the cooked wood chips, and black liquor between two large metal disks with ridged surfaces. Typically, one of the discs rotates and one is stationary causing a shearing action on the blown material as it passes through the gap between the disks. The amount of energy that goes into the pulp is controlled by the size of the gap the material passes through. Decreasing the gap increases the energy applied, and the amount of work done on the material. By applying different amounts of energy to the material, the effects on the pulp can be controlled. The gap is controlled by positioning devices that move the rotor towards or away from the stater or by a motorized screw drive.