Calendering – Hard Nip

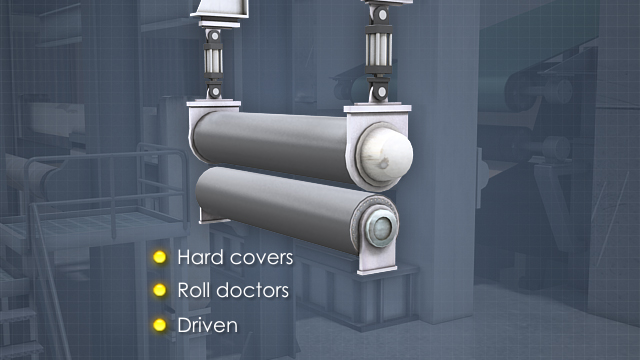

Hard nip calendering is used to smooth the surface and control the caliper or thickness of the sheet before it is wound onto a reel. Some sheet compaction or pressing also occurs. At the end of this module, you will be able to describe the purpose of hard nip calendering and describe the main components of a hard nip calender.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe the purpose of hard nip calendaring • Identify sheet and calender operating variables that affect calendering • Describe the differences between single-nip and multi-nip calender stacks • Identify the safety hazards associated with calender stacks • Identify and describe the main components of a hard nip calender • Explain how roll deflection can be used to control the caliper profile of the sheet • Explain how zone profiling can be used to adjust the caliper profile of the sheet

Specs

Frequently Asked Questions

Why are multi-nip calender stacks with 3 or more rolls used on some paper grades?

What is a “queen roll”? What is a “king roll”?

What adjustment can be made at the calender stack to “fix” soft edges at the reel without changing the nip load?

What if only one edge is soft?

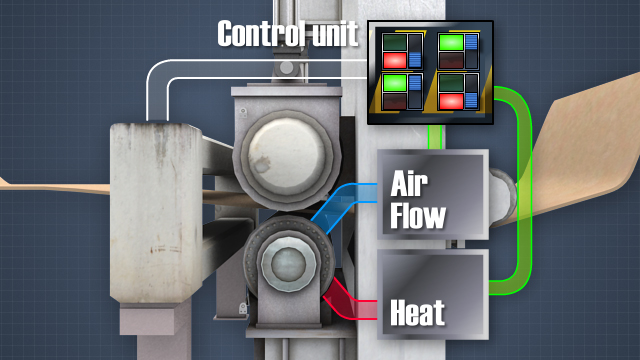

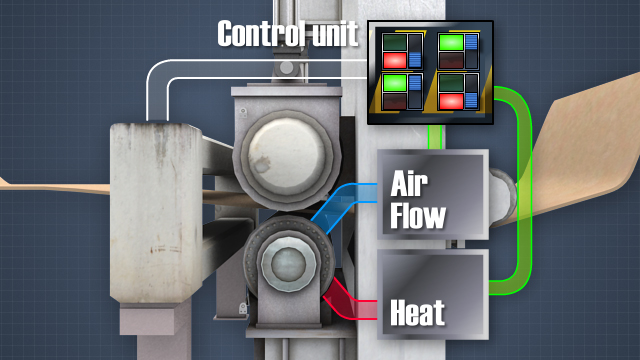

What is “zone profiling”?

Sample Video Transcript

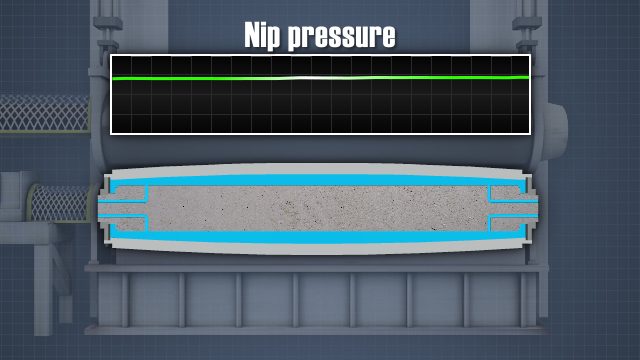

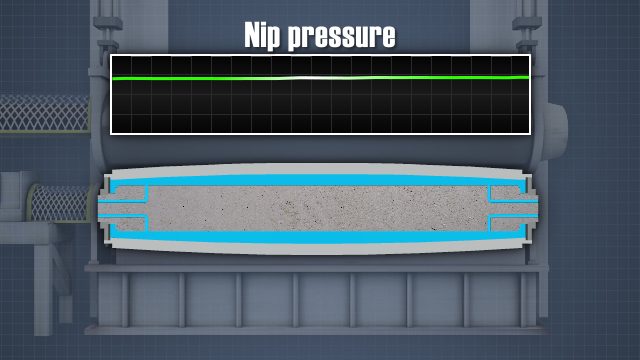

On single-nip calenders, operators typically have control of three parameters to adjust nip pressure profiles: the front load, back load, and crown deflection. The front and back loads create the overall nip load, while the crown deflection affects the nip pressure profile. These three parameters can be used to control the caliper profile of the sheet as follows. If both edges are soft at the reel because the caliper is low on the edges, increasing the roll deflection will increase the caliper at both edges without changing the overall nip load. Conversely, if both edges are hard, the roll deflection can be reduced.