Centrifugal Cleaners

Purpose, design, and operation of centrifugal cleaners installed in paper machine thin stock systems. Effect of pressure drop, feed consistency, and reject rate on cleaner efficiency is covered, followed by a discussion of cascade cleaner systems.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe the purpose of centrifugal cleaners • Describe the design and operation of forward cleaners • Describe the benefits of cascaded cleaning systems • Describe the design and operation reverse and dual cleaners • Describe factors that affect cleaner efficiency • Describe the effect that cone size has on cleaning

Specs

Frequently Asked Questions

What is the purpose of cleaners?

What are forward cleaners?

What is a cascade cleaner system?

What are reverse cleaners?

Why is pressure drop important for cleaning efficiency?

Sample Video Transcript

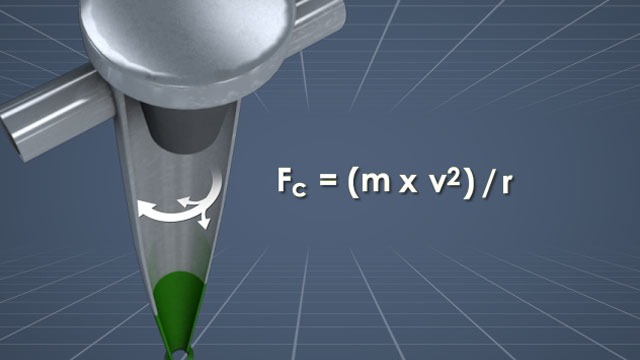

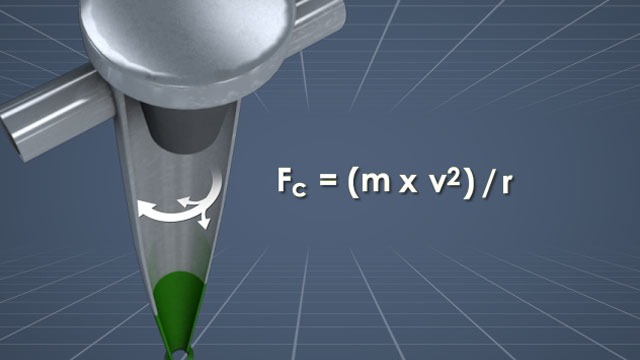

In forward cleaners, the incoming stock is fed to each cleaner tendentially or roughly parallel to the wall of the point of entrance near the top of the cone. Once inside, the fluid pressure created by the cleaner supply pump is converted to rotational motion as the stock forms a vortex inside the tapered cylinder. The vortex carries the pulp fibers and other solid particles out toward the walls, where they turn and then travel downward. The decreasing cone diameter increases the velocity of the rotating stock. This creates the centrifugal force that moves the heavier or more dense components out towards the walls. At the bottom of the cleaner cone, these dense components are discharged to the rejects line. Meanwhile, the lighter components, including most of the pulp fibers, are less affected by the centrifugal force, and so they move inwards toward the center of the vortex. The fibers and water in the center of the vortex travel upwards and exit through an opening at the top center of the cone.