Continuous Cooking Introduction

This course provides an overview of a basic continuous digester cooking system. It describes the general flow of fiber through the cooking process, the difference between batch and continuous cooking, the variables that are important to the cooking process, and the major pieces of equipment.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Identify the three main components of wood

• Describe mechanical, chemical and semichemical types of pulping

• Differentiate between batch and continuous cooking

• Describe the major steps involved in cooking

• Identify the process flow of wood chips and chemicals through the continuous cooking process

• Recognize and describe the major chip and process variables involved in cooking

Specs

Frequently Asked Questions

What does “cooking” a wood chip refer to?

What are some of the advantages of continuous over batch cooking?

How are wood chips transferred into a continuous digester?

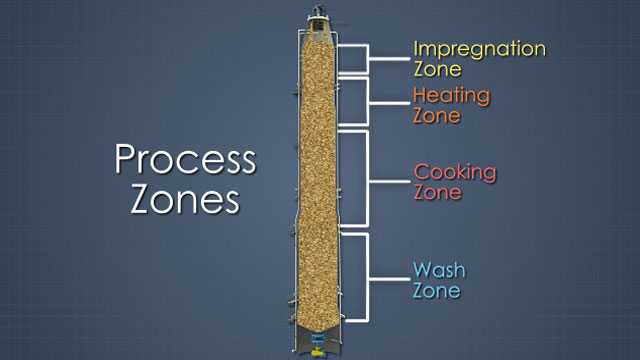

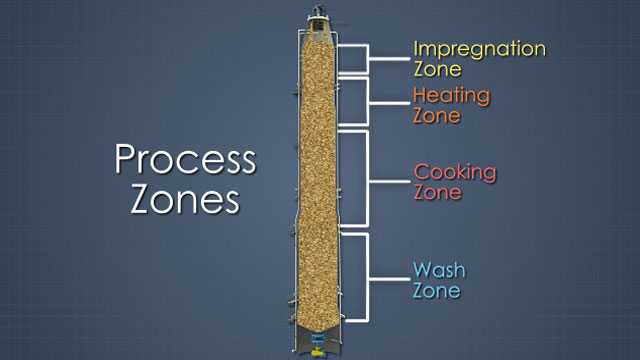

How are different process zones established in a continuous digester?

What are some of the factors which affect the cooking of wood chips?

Sample Video Transcript

Continuous digesters can be up to 200 feet tall and range in diameter from 12 to 18 feet. Chips and cooking liquor are delivered to the top. Excess liquor that was used to transport the chips is removed and the chips slowly move as a plug down the length of the digester over a period of several hours. Screened outlets along the outer wall of the digester allow liquor to be withdrawn at different elevations down the digester. A liquor distribution system, which consists of a set of concentric pipes extending down from the top of the digester, permits liquor to be introduced into the flow of chips at multiple elevations inside the digester.