Continuous Digesters – Hydraulic

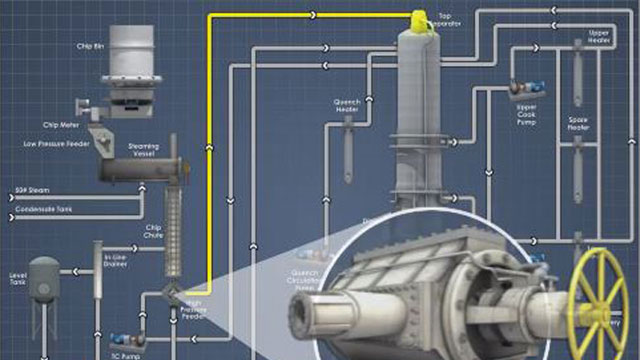

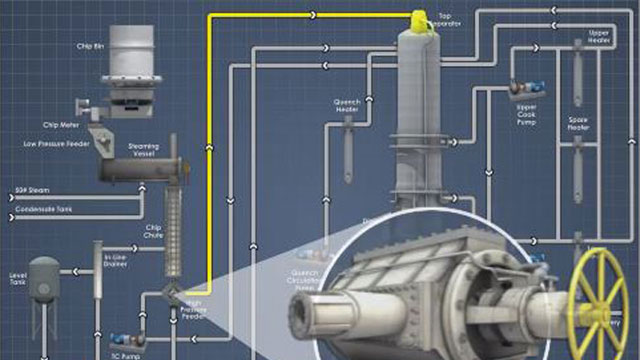

In a continuous digester, wood chips and liquor are continuously fed to, and withdrawn from, a pressure vessel. Continuous cooking offers some distinct advantages over batch cooking, including reduced space requirements, improved cooking control, and improved energy efficiency. Many variations of continuous digester equipment and process conditions have been used. Some digesters are hydraulically filled, while others utilize a vapor phase. This module covers the basic principles of operation of hydraulically filled continuous digesters.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe some of the advantages of continuous cooking

• Identify the purposes of a continuous digester chip feed system

• Describe how process zones are established in a continuous digester

• Describe the advantages of using an impregnation vessel

• Identify some of the guidelines which maximize the benefits of continuous cooking

Specs

Frequently Asked Questions

What are some of the goals of the chip feed system on a continuous digester?

Why do chips need to be impregnated with liquor before being cooked in a continuous digester?

What is one way chips are heated in a hydraulic digester?

What is an impregnation vessel?

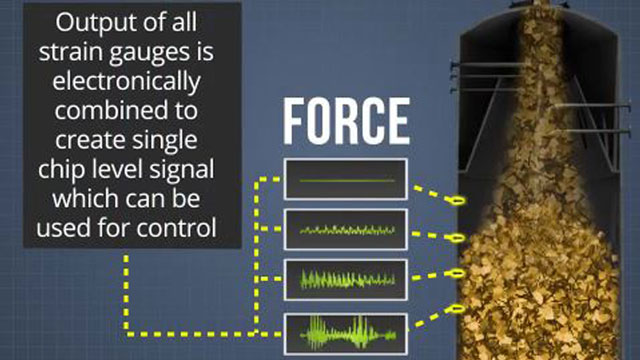

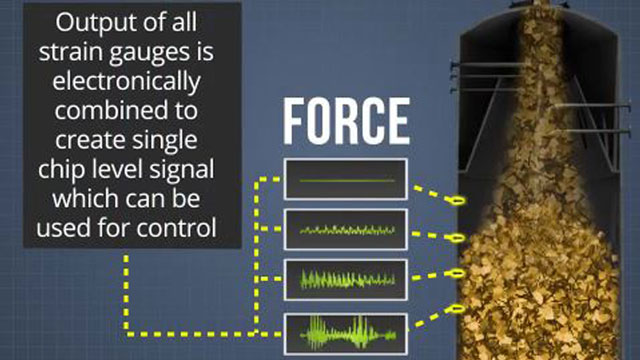

How is chip level usually determined in a hydraulic digester?

Sample Video Transcript

By controlling the introduction and withdrawal of liquor at different elevations in the digester, process zones of varying conditions can be established along the length of the digester. The temperature and chemical concentrations of incoming liquor establishes the conditions of the zone between the liquor inlet and the screens where the liquor is withdrawn. In some zones, the liquor is withdrawn at a higher elevation than where it is injected, resulting in the liquor flowing upward or counter currently to the down flowing chips. Counter current liquor flow results in good mixing but can lead to chip column movement problems.