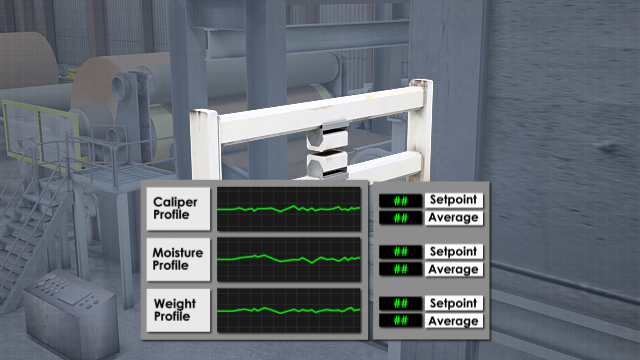

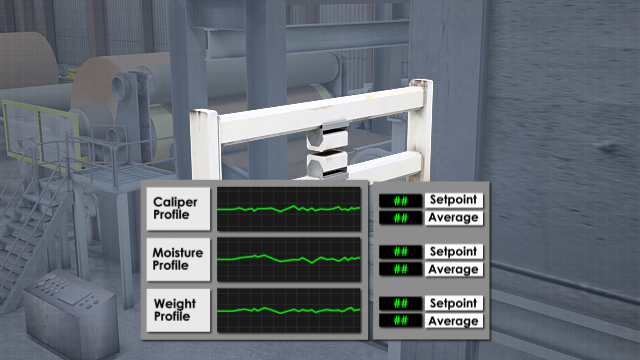

Dry End QCS Scanner

The QCS scanner is a device located just before the reel that provides continuous measurement of key dry sheet properties. This module will describe safety guidelines for working around a dry end QCS scanner, how QCS scanners operate, and different types of sensors used.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe safety hazards and safe work practices associated with a dry end QCS scanner • Explain how QCS scanners operate • Identify and describe the type of sensors used to measure moisture, weight, and caliper • Explain how moisture, weight, and caliper profile issues are handled by the control system • List the benefits of improved profiles

Specs

Frequently Asked Questions

What variables are typically measured by dry end QCS scanners?

Can I work safely around a dry end QCS scanner that contains a radioactive measuring device?

Where are caliper adjustments made on the machine?

Are any of the profiled variables related to each other?

What are the benefits of flatter sheet profiles?

Sample Video Transcript

The QCS Scanner is a device located just before the reel that provides continuous measurement of key dry sheet properties. The scanner consists of two heads and a support frame. Sensors are installed on the heads, which are mounted on opposite sides of the sheet directly across from each other. The two heads move back and forth across the sheet together and send their results to the QCS computer. The data that is measured and recorded is compared against set points and used to make required adjustments to the process.