Motor Overload Protection

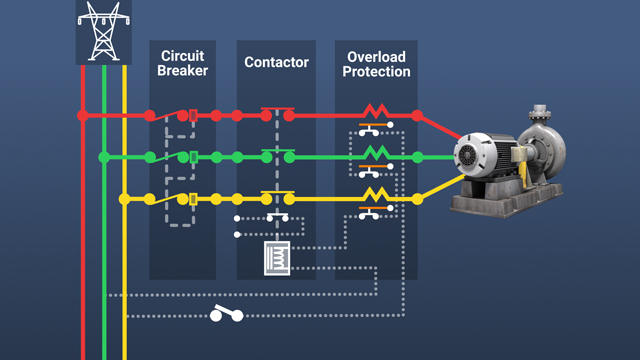

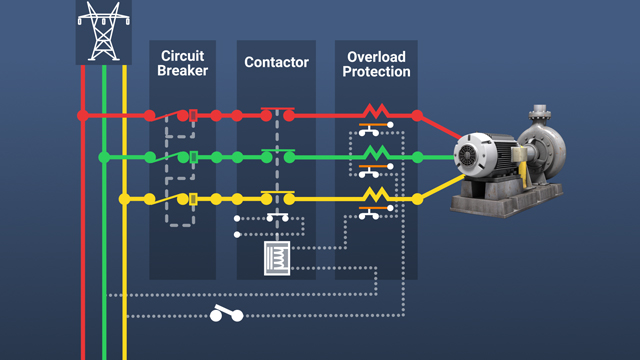

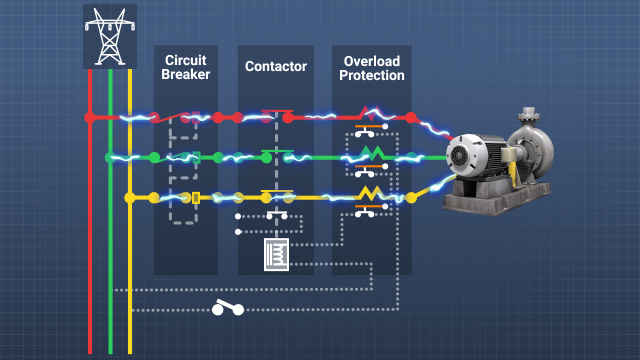

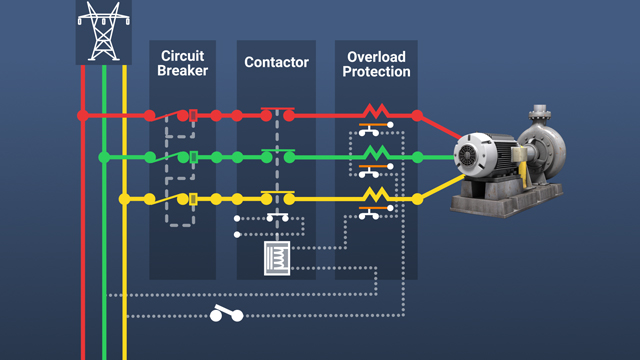

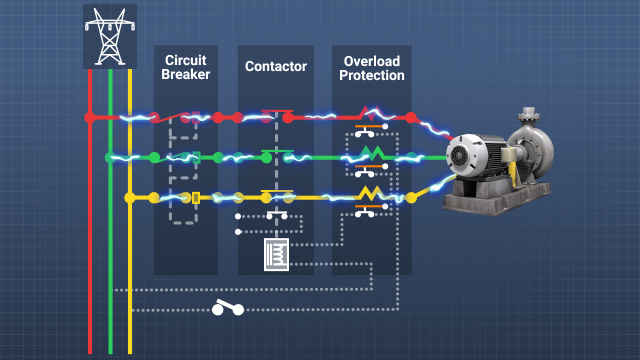

Large alternating current motors are vital to modern life and industry. While motors are relatively simple devices, they can be installed or operated incorrectly or develop operational problems. For protection of the motor and for safety reasons, electrical motors require protective devices on their power supply systems. Circuit breakers and fuses are used to provide protection from very high-current short circuits and ground faults. Overload devices are used to protect from longer period, moderate overcurrent events. This module will focus primarily on the role and function of the overload protection devices.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

- Describe the purpose of fuses and circuit breakers

- Differentiate between a short circuit fault and an overload

- Explain the principles of operation behind thermal overload devices

- List some causes for motor overload

- Explain the principle of operation behind magnetic overload devices

- Explain the principle of operation behind electronic overload devices

- Describe the NEMA trip class numbering system

Specs

Frequently Asked Questions

What is the difference between circuit breakers and overload protection devices?

What are some conditions that can lead to motor overloading?

How does a bimetallic overload device work?

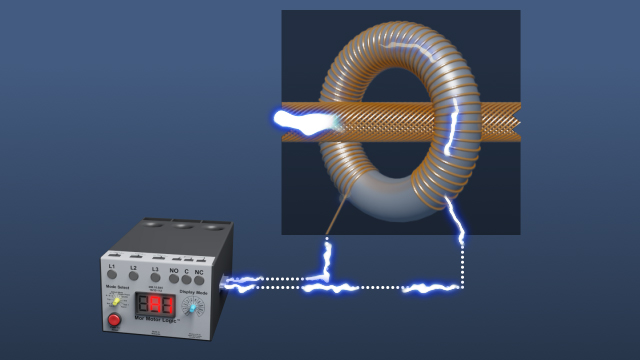

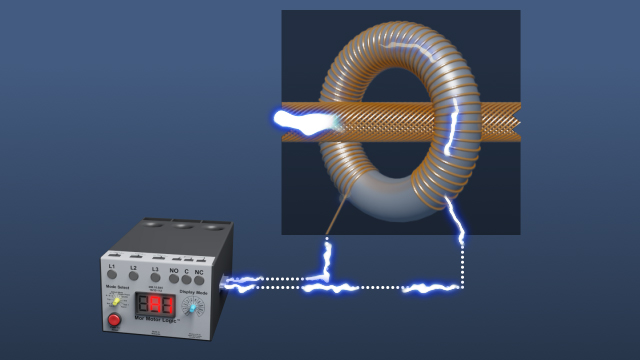

What role do current transformers play in overload protection?

What does the NEMA trip class of an overload device indicate about the device?

Sample Video Transcript

There are several types of overload devices which can be placed in line with a motor winding to prevent damage from overheating. Two types of devices rely on a thermal element for protection. The first uses a bimetallic strip. A bimetallic strip consists of two strips of metal bonded together. As the temperature of the strip increases, the metals expand at different rates, causing the strip to bend. This bending upon heating can be used to make or break contacts in an overload device. In the diagram shown, an electric heater in series with the winding of a motor generates heat in proportion to the current flowing through the motor. If the current increases, the heater generates more heat, the bimetallic strip bends and opens the contacts which trips out (or stops) the motor.