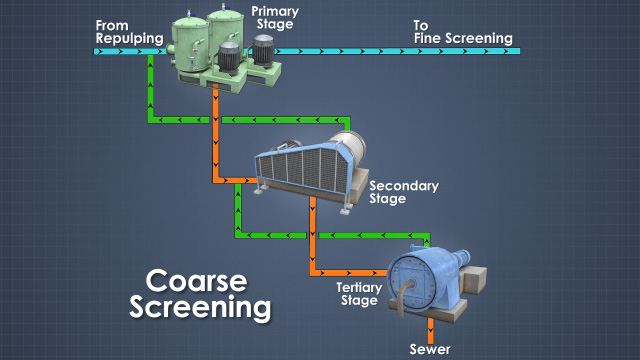

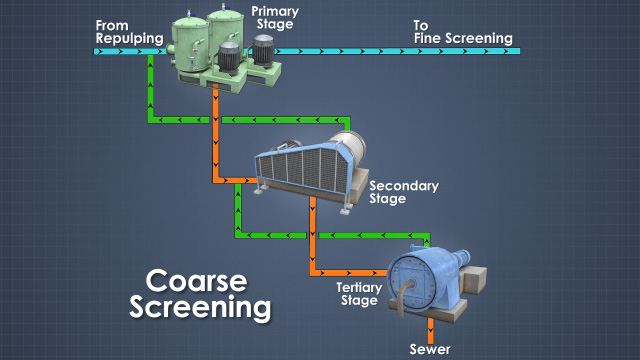

OCC – Coarse Screening

OCC plants convert recycled old corrugated containers into pulp that can be used on paper and board machines to make valuable pulp and paper products. After repulping, the OCC pulp contains some contaminants, such as staples, glass debris, and sand, as well as fiber flakes and bundles that were not separated into individual fibers during repulping. To remove these undesirable materials, the pulp slurry goes through one or more screening processes to remove the contaminants that are larger than fibers. This course describes the initial, “coarse screening” process used to remove the largest contaminants from the OCC pulp.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Explain the purpose of coarse screening

• Describe why coarse screening systems often use multiple stages

• Identify and describe the major components of cylindrical screens

• Identify and describe the major components of disk screens

• Describe the process flows for coarse screening

• Identify the characteristics of screen openings which influence screen performance

• Explain why a different design is typically used in the final stage of coarse screening

• List safety hazards and guidelines associated with coarse screening systems

Specs

Frequently Asked Questions

What is the goal of coarse screening in an OCC facility?

What is the purpose of the rotor in a cylindrical screen?

What process variables can be used to determine if a screen is plugged?

What is the primary advantage a disk screen offers over a cylindrical screen?

Why do some screening systems use multiple stages of screening?

Sample Video Transcript

In cylindrical pressure screens, the OCC pulp is usually fed through the inlet piping into a space between the rotor and screen basket, and the rotating motion of the rotor imparts motion to the pulp slurry. The incoming flow plus the rotating motion of the rotor help push the pulp slurry against the screen basket. Depending on the size of the openings, particles of different sizes and shapes pass through. Depending on the screen design, the pulp can travel either inward or outward through the openings. The portion of the pulp that successfully passes through the screen openings is called the accepts while the portion that does not pass through is called the rejects.