Paper Machine Drying

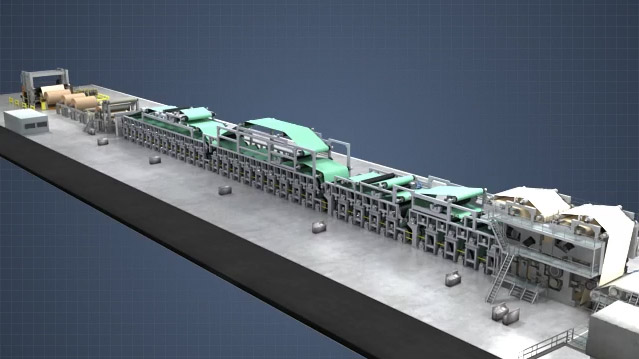

On conventional paper and board machines, the energy required to dry the sheet to the desired moisture target at the reel is supplied by a series of rotating, steam-heated, dryer cylinders. These cylinders, or “cans,” are grouped into multiple drive sections, which go progressively faster in order to adjust for machine direction stretch and to maintain sheet tension. This module will provide a general overview of the drying section of a paper machine.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe the design and operation of a typical multi- cylinder dryer section • List the objectives of paper machine drying • Define the terms “latent heat,” “boiling point,” “evaporation,” “condensation,” “superheated,” and “blow-through steam” • Identify, describe, and state the purpose of dryer syphons, dryer fabrics, pocket ventilation systems, hood makeup air and exhaust systems, and blow boxes • Describe heat transfer and mass transfer during sheet drying • Describe the three phases of drying – sheet heating, constant rate, and falling rate • List the factors that affect sheet drying • Identify and describe single-tiered and double-tiered dryer sections • Explain the purpose of blow-through steam • Describe the two ways blow-through steam can be recovered for reuse • Identify and describe safety hazards and safety guidelines for multi-cylinder dryer sections

Specs

Frequently Asked Questions

What is the purpose of dryer fabrics on multi-cylinder machines?

What is the purpose of dryer hoods?

What are single-tiered dryer sections?

Why are single-tiered dryer sections often followed by double-tiered sections?

What is the purpose of pocket ventilation systems?

Sample Video Transcript

On a paper or board machine, the drying process involves both heat transfer and mass transfer. Heat transfer is the movement of thermal energy due to a temperature difference. In multi-cylinder drying systems, the driving force for heat transfer is the temperature difference between the sheet and the dryer cans. This process is called contact drying, because the sheet directly contacts the dryers. Heat transfer occurs when the steam condenses inside the dryer can and gives up its latent heat to the inside surfaces. The heat energy from the condensing steam is then transferred by conduction through the dryer cans’ cast iron shell to the sheet. Because the steam inside the dryer is saturated, the steam temperature is directly related to the steam pressure.