Refrigeration – Compressors, Valves and Piping

The main purpose of a vapor-compression refrigeration system is to transfer heat from a cooler space to a warmer environment. The system has four main components: a compressor, a condenser, an expansion valve, and an evaporator. The refrigerant flows continuously through these four components as it is alternately compressed and expanded, changing from a liquid to a vapor and back as it absorbs and releases heat.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

By the end of this course, you will be able to:

- State the purpose of the compressor in the vapor-compression refrigeration cycle

- Describe hermetic, semi-hermetic, and open-type compressor housings

- Describe the design and operation of reciprocating, rotary vane, scroll, screw, and centrifugal compressors

- List major design considerations for a refrigeration piping system

- Discuss the use of copper, aluminum, and steel in refrigeration piping systems

- Discuss soldered, brazed, flared, and quick-connect piping connections

- Describe the operation of various types of expansion valves

- State the functions of accumulators, receivers, filter-driers, and common valve types in refrigeration systems

Specs

Frequently Asked Questions

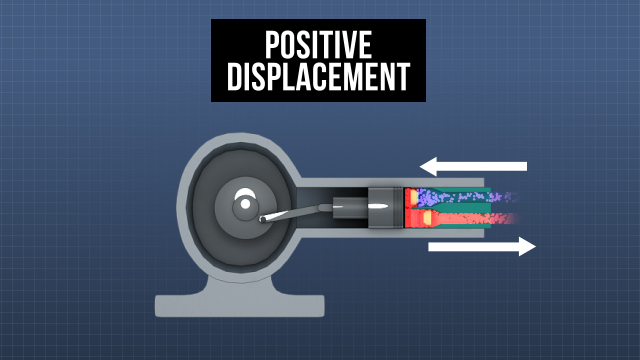

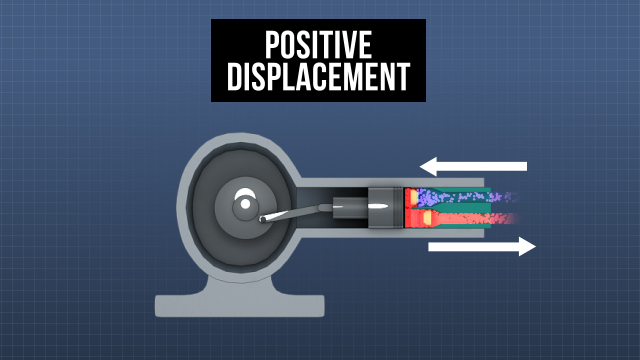

What is a “positive displacement” compressor?

What other types of compressors are there?

What are some of the line size considerations in refrigeration system design?

Why is it important to minimize line lengths in refrigeration systems?

Why aren’t capillary tubes used as expansion valves in every system, since they are low cost and easy to replace?

Sample Video Transcript

Reciprocating compressors (or piston compressors) consist of one or more intake valves (also called the intake manifold), one or more pistons in cylinders, exhaust valves, a crankshaft with connecting rods and bearings, and an oil sump or lubricating system. Compressors with multiple pistons are classified by the letter that resembles the arrangement of their pistons (for example, “V” or “W”). The pistons are driven in a reciprocating action by the crankshaft and connecting rods, and the intake and exhaust valves open and close in response to pressure changes inside the cylinders. The crankshaft is usually driven by an electric motor. In smaller units, the crankshaft and connecting rods are often lubricated by “splashing” oil from an oil sump. Higher capacity units often have a pressurized lube system.