Size Presses

Surface sizing is commonly used on grades of paper and board that will be coated and/or printed. The traditional purposes of surface sizing have been to improve the sheet’s resistance to the penetration of fluids and to improve certain sheet properties. Traditionally, a starch-based sizing solution is applied to both sides of a fully dried sheet in a two-roll nip at a “size press” that is located between drying sections. This course discusses the design and functions of a size press.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• List the two traditional purposes of surface sizing • List some of the materials that can be used in surface sizing solutions • Identify and describe pond-style size press designs, including vertical, horizontal, and inclined size presses • List sheet variables that affect the performance of pond-style size presses • List sizing solution variables that affect the performance of pond-style size presses • List equipment variables that affect the performance of pond-style size presses • Identify and describe film-type size press designs • List the advantages of film-type size presses over pond-style size presses • Identify and describe safety hazards and safety guidelines for size presses

Specs

Frequently Asked Questions

What is the purpose of surface sizing?

Where is surface sizing usually applied to the sheet?

How is cationic starch different from regular starch?

Where is surface sizing usually applied to the sheet?

Why do sheet breaks often occur at the size press?

Sample Video Transcript

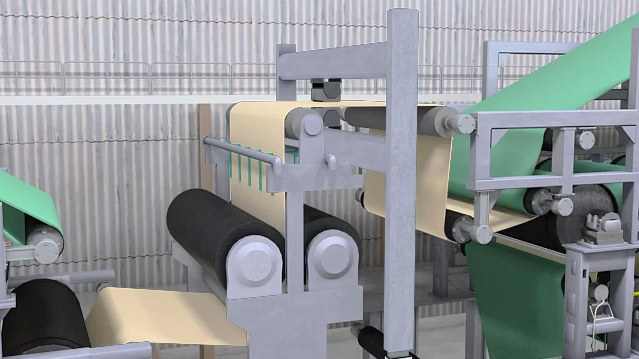

A conventional pond-style or flooded nip size press utilizes two driven rolls pressed together in a vertical, horizontal, or inclined arrangement. The goal in each is to flood the ingoing nip with sizing solution on both sides of the sheet. The sheet absorbs some of the solution and the excess is removed by the nip. The solution is allowed to overflow or is collected in a pan and is continuously recirculated. The vertical size press provides the easiest sheet run but size application is unequal on the two sides of the sheet. The horizontal size press solves the problem of unequal application but has an awkward sheet run. The inclined size press is a compromise of the other two.