Stock Approach – Deaeration

Entrained air in the dilute stock supplied to the headbox of a paper or board machine can cause problems with drainage, foam, sheet formation, and overall process stability. Therefore, mechanical deaeration is sometimes required. This module will identify four ways to keep entrained air out of paper and board making processes and describe the three ways mechanical deaerators remove air from stock.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

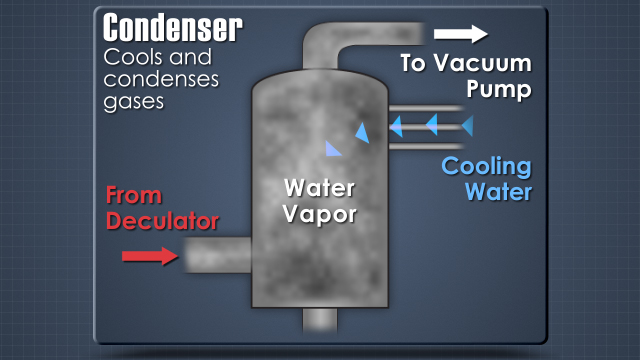

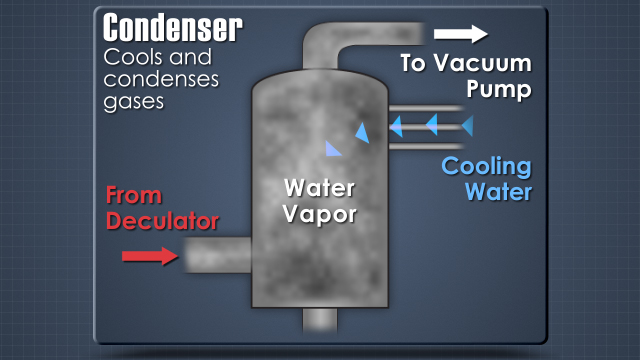

• List and describe three forms of entrained air in stock suspensions and white water • Identify four ways to keep entrained air out of paper and board making processes • Identify the negative effects of, and potential benefits of removing, entrained air in stock • Identify and describe the key equipment • Identify and describe primary process flows • Describe the three ways mechanical deaerators remove air from stock • Explain why a stand-alone deaerator might be used instead of a combination cleaner/deaerator • Describe the function of the condenser and vacuum device in the vacuum system • Identify potential causes for a sudden drop in vacuum, deaerator flooding, and low vacuum or system instability

Specs

Frequently Asked Questions

Are there multiple forms of entrained air?

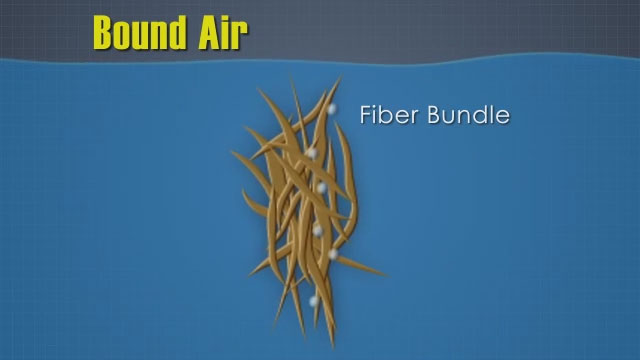

What are the differences between free air, bound air, and dissolved air?

Is deaeration necessary on every machine?

How do deaerators remove entrained air from the stock suspension?

Can a deaerator cause pulsations in the stock flow to a headbox?

Sample Video Transcript

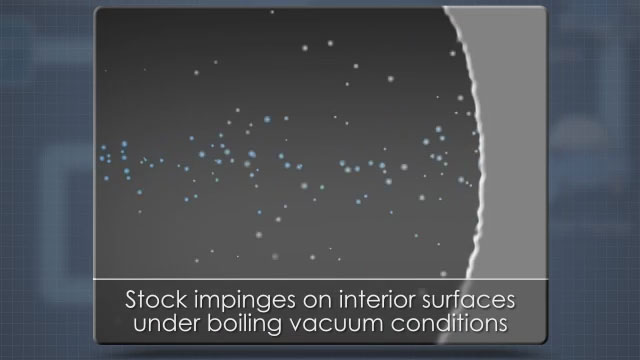

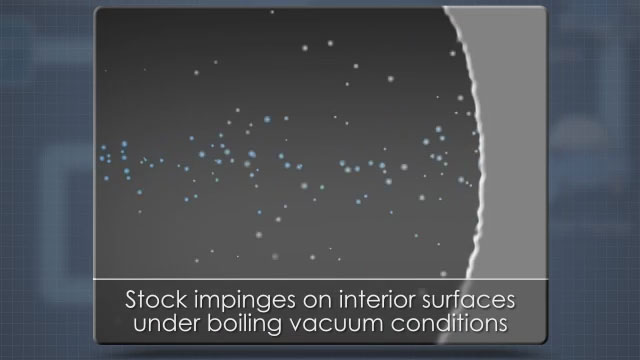

To maximize the removal of entrained air by mechanical means, the stock must be exposed to a vacuum level that is sufficient to cause the stock to boil. This causes the free air bubbles to break and the dissolved air to come out of the water, be sprayed to maximize the surface area of the stock that is exposed to the vacuum, and impinge upon a hard surface to break the bound air bubbles away from the fibers. Most deaerators are designed to accomplish all three: boiling, spraying, and impingement.