Supplemental and Recycled Fiber – Recycling Fiber Overview

Wood fiber accounts for more than 90% of the raw material used in the production of paper and board products, and it can come from a variety of sources. These sources can be slushed virgin fiber that is produced onsite, market pulp from other pulp mills, or recycled/secondary fiber. This course will cover recycled fiber sources and the processes that are used to turn that fiber into clean papermaking stock

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Define the terms: “market pulp,” “recycled fiber,” “pre-consumer waste,” and “post consumer waste”

• State the primary goal of a recycled fiber facility

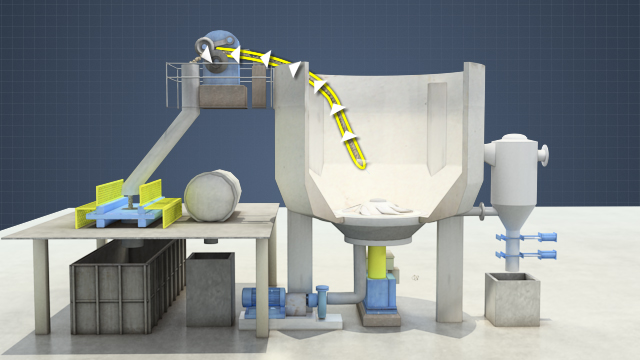

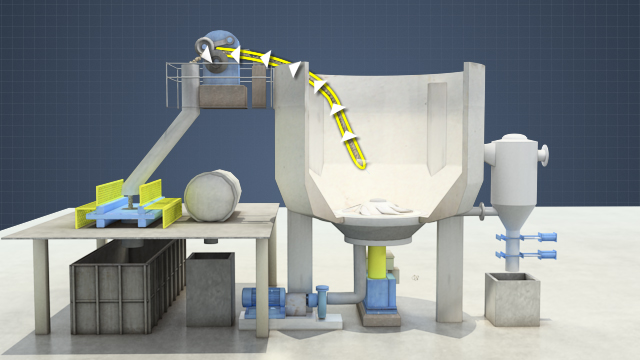

• Identify and describe the main components of a repulper

• List the three physical characteristics which are used to separate fiber and contaminants

• Describe the principle behind centrifugal cleaning

• Explain the principle of separation that applies to the screening process

• Identify and describe the major components of a cylindrical pressure screen

• Describe how flotation is used to separate fibers and ink

• List safety hazards and safety guidelines associated with repulping and cleaning equipment

Specs

Frequently Asked Questions

What is the primary goal when fiber is recycled?

How do high density cleaners clean incoming pulp?

Why are multiple stages of screens used?

What type of screen is best suited for use as a coarse screen if the pulp has high levels of contaminants?

How are ink particles separated from fibers in a flotation deinking cell?

Sample Video Transcript

Centrifugal cleaners are devices which separate fibers and contaminants on the basis of their respective densities. The body of a centrifugal cleaner is a slender cone with its largest diameter at the top. The pulp slurry enters tangentially near the top of the cleaner body at a relatively high velocity. As the slurry enters, it spins within the body and creates a vortex. Centrifugal force moves the denser materials in the slurry toward the outside wall, where they drop down toward the bottom of the cone. There is less outward force on the fibers, so they migrate to the center of the vortex and travel upwards to the accepted stock outlet.