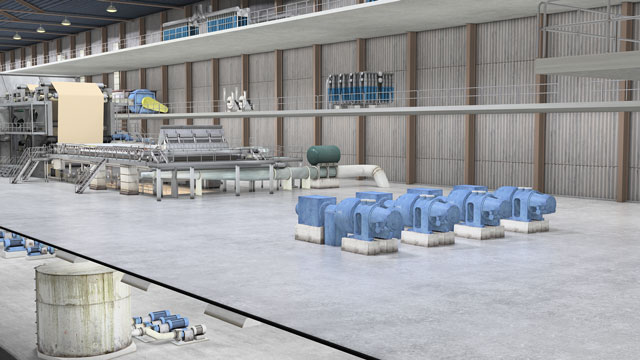

Thick Stock System Design

The thick stock system is where the papermaking process begins. In this system, pulp fibers are blended together, refined, diluted, metered, and some additives may be added. This course discusses the principles of the thick stock system as well as the key equipment used, how stock blending is achieved, as well as how high density chests and stock thickeners work.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• List the four principle objectives of the thick stock system • Identify safety hazards and safety guidelines related to thick stock systems • Identify and describe key equipment used in thick stock systems • Identify and describe primary process flows in thick stock systems • Describe stock blending • List common features of stock storage chests • Describe how high density chests work • Describe how stock thickeners work

Specs

Frequently Asked Questions

Why is it important to control stock consistency in the thick stock system?

Where is consistency typically controlled in a thick stock system?

Why is pH control important in the thick stock system?

What is the purpose of savealls in thick stock systems?

What is the role of the machine chest in the thick stock system?

Sample Video Transcript

The thick stock system has four principle objectives. One, to blend the most cost effective combination of fibers, fillers, and chemical additives. Two, to control stock consistency and stock pH. Three, to buffer or dampen variations in stock flow rates, consistencies, and pH. And four, to refine the pulp fibers. Each paper or board machine has their own unique requirements of the thick stock system depending on the type of paper or board being produced. All mills have the same end goal, however, that is to ensure that a uniform stock of high quality is supplied to the thin stock system.