Vacuum Pumps, Blowers, and Ejectors

Liquid-ring vacuum pumps, centrifugal blowers, and steam ejectors are three devices that are commonly used to produce vacuum. This module explains how liquid-ring vacuum pumps create vacuum, explains why vacuum pump seal water should be cool, and describes the operation of liquid-ring vacuum pumps, single-stage and multi-stage centrifugal blowers, and steam ejectors.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• List safety hazards and safety guidelines associated with vacuum pumps, vacuum blowers, and steam ejectors • Explain how liquid ring vacuum pumps create vacuum • Explain why vacuum pump seal water should be cool • Identify and describe the main components of liquid ring vacuum pumps, centrifugal blowers, and steam ejectors • Identify and describe key process flows for a liquid ring vacuum pump • Describe the operation of liquid-ring vacuum pumps, centrifugal blowers, and steam ejectors

Specs

Frequently Asked Questions

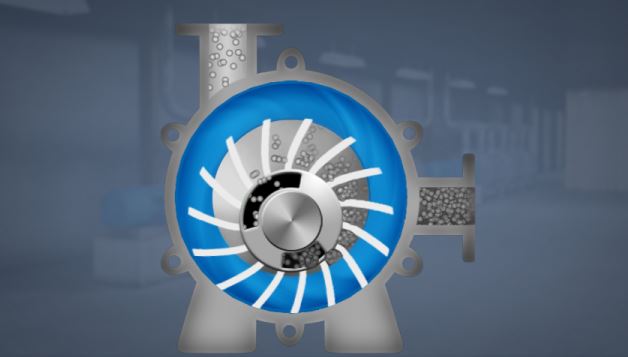

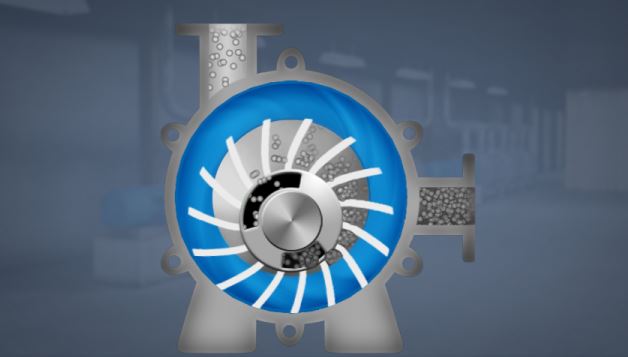

How is the seal water used in liquid-ring vacuum pumps?

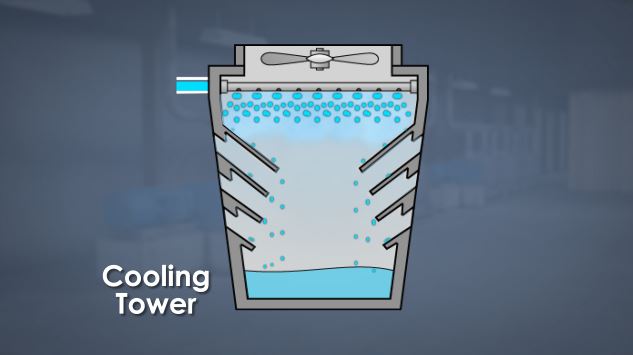

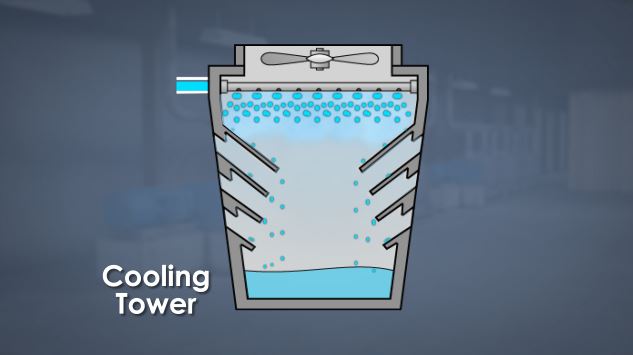

Why is it important for vacuum pump seal water to be cool?

How is vacuum used on a paper machine?

What is the difference between a centrifugal fan and a centrifugal blower?

Is a thermocompressor a type of steam ejector?

Sample Video Transcript

Single stage blowers are constant speed, rotating machines. Air flows through single stage blowers are controlled by guide veins, either by a single set of inlet guide veins or by two sets of guide veins. A dual vein, single stage blower, uses two sets of veins, one on the inlet side and one on the outlet side. So they cost a bit more initially, but this design is more efficient. The outlet guide veins are used to control the aerodynamic shape or flow pattern of air as it is released from the tip of the impeller. So they control the air flow through the blower.