Wet Edge Control

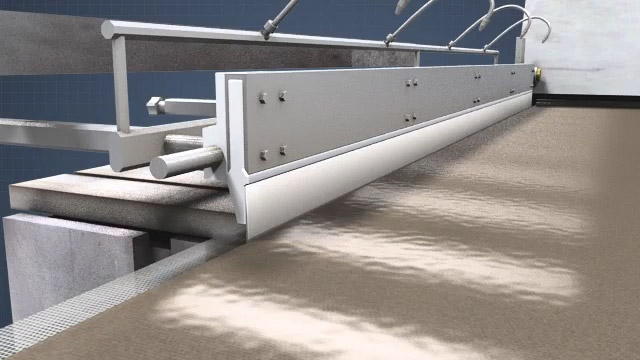

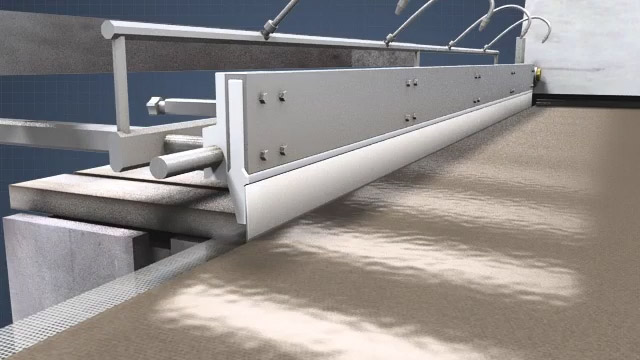

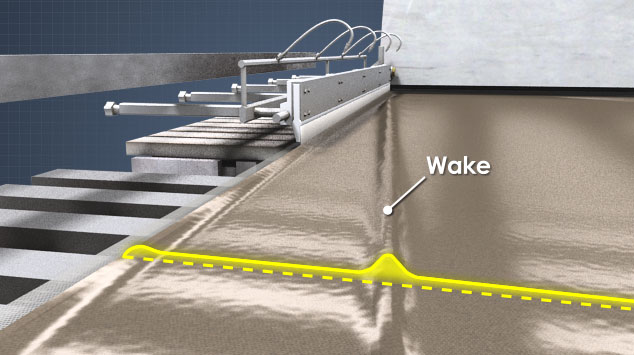

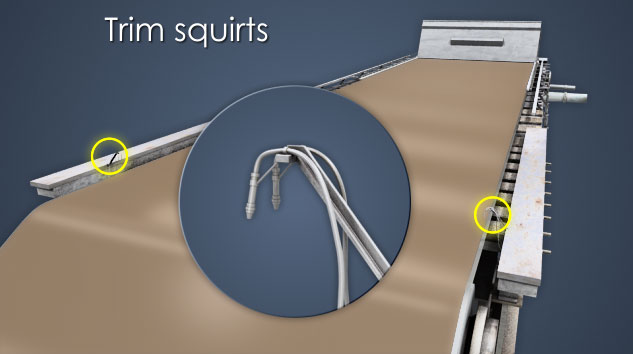

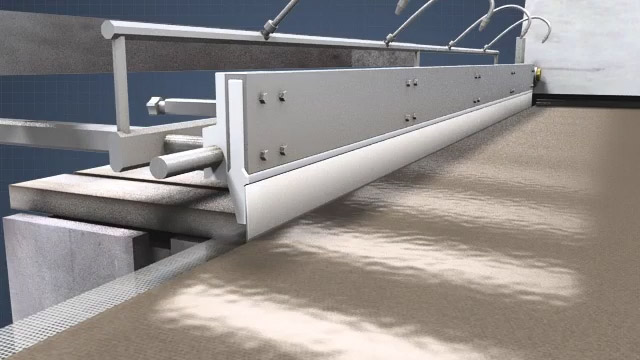

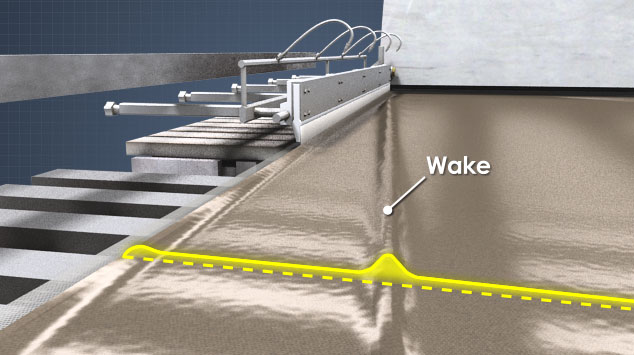

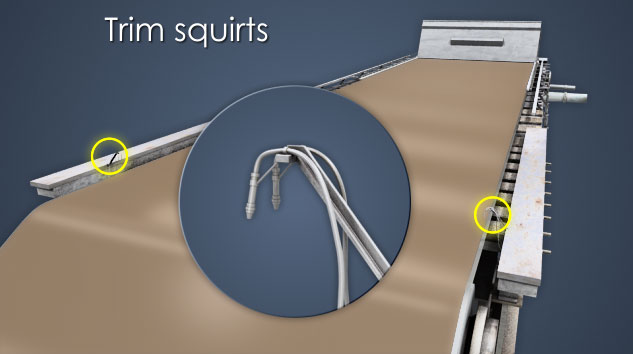

Deckles run along the wire edges adjacent to the headbox to keep the stock on the wire until it has dewatered sufficiently. Curling boards and water jet deckles can help minimize the formation of deckle wakes. Edge showers are used to keep the deckles, curling boards and wire edges clean and lubricated. Trim squirts are used to trim off the edges at the end of the former and establish the sheet width into the press section. They must all be installed and positioned properly to minimize wear and prevent edge profile and edge transfer issues. This module will describe the function and operation of each of these device.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Identify where sheet formation is established on a paper or board machine • Describe the relationship between sheet formation and sheet properties • Describe why wet edge control is important and identify sheet properties affected by edge control issues • Identify and describe the functions of deckle boards, curling boards, edge showers, and trim squirts

Specs

Frequently Asked Questions

Why do sheet breaks on a paper or board machine often originate at the sheet edges?

What is the purpose of deckle boards?

Why have water jet deckles replaced deckle boards on many paper and board machines?

Why is the position of the end deckles on forming section suction boxes so critical?

What is the purpose of curling boards?

Sample Video Transcript

Normally, showers are installed to keep the deckles clean and clear of stock buildup, and provide lubrication between the flexible strips and the wire. As machine speeds increased, it was observed that the stock tended to rise up on the vertical surfaces of the stationary deckle boards, and then flow back down at a reduced speed. This created diagonal waves or wakes in the stock, which led to problems with uniformity at the edges of the sheet.